Железопътната количка KMG-11,4 се използва при извършване на маневрена дейност с подвижен състав в района на заводски, пристанищни, складови и гарови железопътни клонове. Количката работи в комплект с универсален виличен мотокар с товароподемност над 3,5 t. Конструкцията на количката е съобразена с изискванията за техническа експлоатация на подвижен железопътен състав, движещ се върху релсови пътища с нормално междурелсие.

Основни предимства на железопътната количка са:

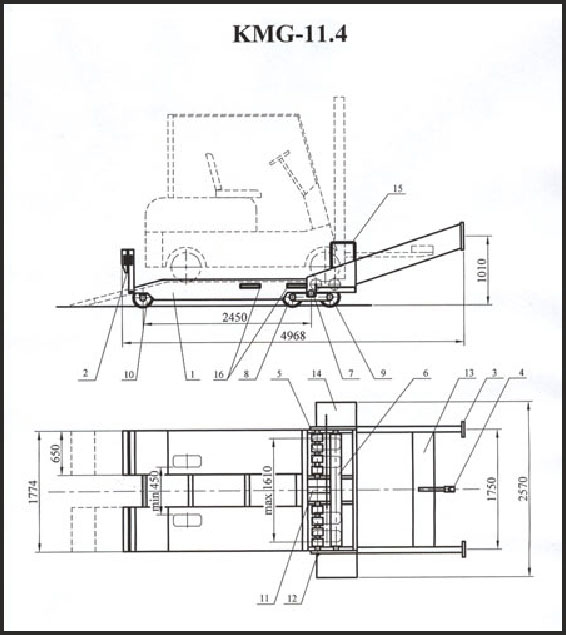

Количката съдържа шаси 1, в задния край на което са шарнирно монтирани подвижни преходни мостчета 2, които в работно положение се закрепват вертикално. В предния край на шасито 1 са установени буферите 3 и теглителната кука 4. Върху шасито 1 са монтирани двигателните 5 и опорните 6 барабани. Ходовата част на количката включва балансирано окачени тележки 7 с две двигателни колооси 8 и 9, и свободно въртяща се задна колоос 10. За увеличаване на сцеплението с двигателните колела на мотокара двигателните барабани 5 са изпълнени с гумирани бандажи. Двигателните барабани 5 са съединени с двигателните колооси 8 и 9 чрез редуктор 11, включващ едностепенна зъбна и две паралелни верижни предавки. Количката е оборудвана с внезапна спирачка 12, която се освобождава ръчно чрез лостово устройство. От двете страни на шасито 1 са монтирани стъпенки 14 и захвати 15 за маневрения персонал. Странично на шасито 1 са предвидени отвори 16 за вилиците на мотокара.

Количката се използва по следния начин. Мотокарът чрез своите вилици подхваща количката в отворите 16, след което я пренася и поставя върху релсовия път. Мотокарът се качва върху количката по преходните мостчета 2. След установяването на двигателните колела на мотокара върху барабаните 5 и 6 вилиците на мотокара се притискат от долната страна на напречната траверса 13 и се освобождава внезапната спирачка 12 с помощта на лостовото устройство. Преходното мостче 2 се повдига и фиксира във вертикално положение, след което системата "мотокар-количка" е готова за работа. Работните задвижване и спиране на системата "мотокар-количка" заедно с прикачния железопътен състав се осъществява чрез съответната трансмисия на мотокара. При аварийна ситуация и при качването и слизането на мотокара се използва внезапната спирачка 12.

| SHUNTING RAILWAY TROLLEY | KMG-11.4 |

| Total mass of the trailing composition, t | 150 |

| Maximum tractive, kN | 11.4 |

| Maximum speed, km/h: | |

| - with an isolation movement | 6.0 |

| - with a shunt | 5.0 |

| Overall dimensions, mm | |

| - length (A) | 1260 |

| - width (B) | 2570 |

| - height (H) | 4968 |

| Width of the wheel gauge, mm | 1435 |

| diameter of the free wheels, mm | 250 |

| Axle formula | 1-Ао-Ао |

| Dead weight, kg | 1850 |

| Total mass of the "forklift truck" system, kg | 6650 |

| Number of the servicing personnel | 2 |